SERVICES

OVER 38,000 SQFT OF MANUFACTURING SPACE

- Plastics / Polymer Custom Injection Molding

- Nylon Braid Machine

- Ultra-Sonic Wire Welding

- Plastics Sonic-Welding

- 3D Printing - Resin/plastic/metal

- Kitting - kit parts with cables / electronics

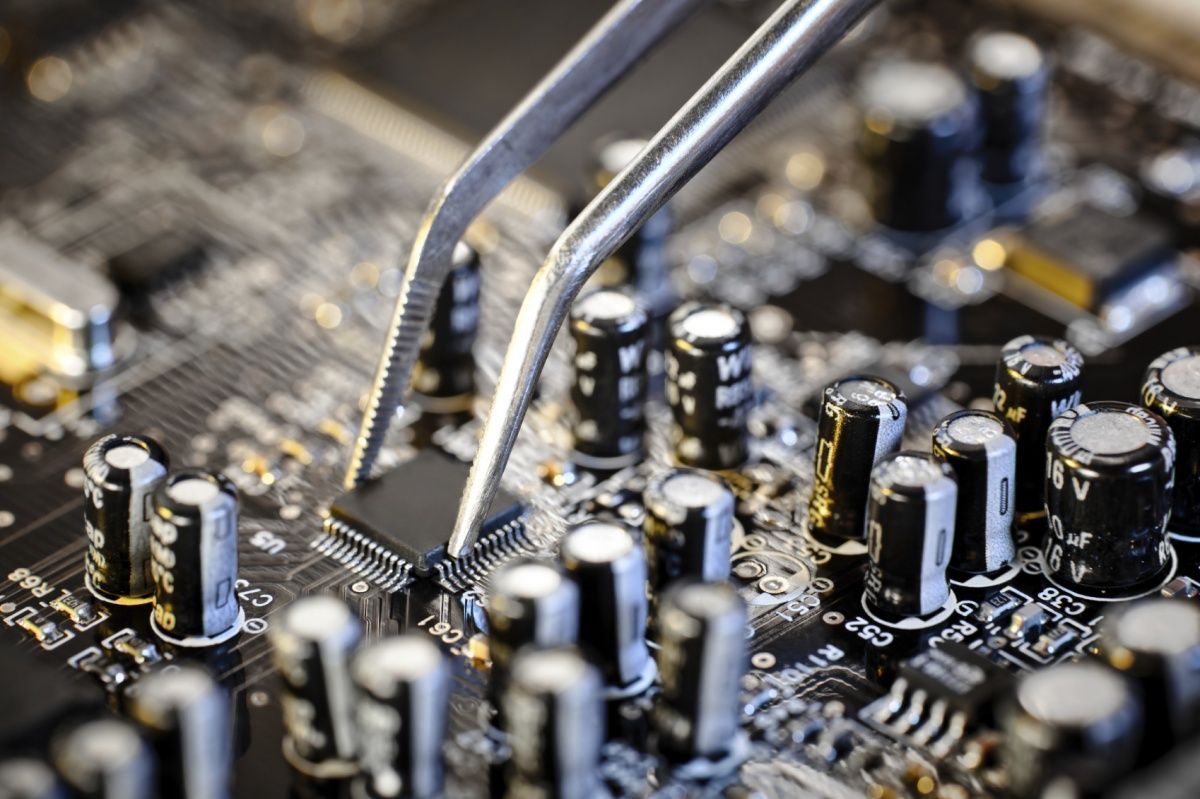

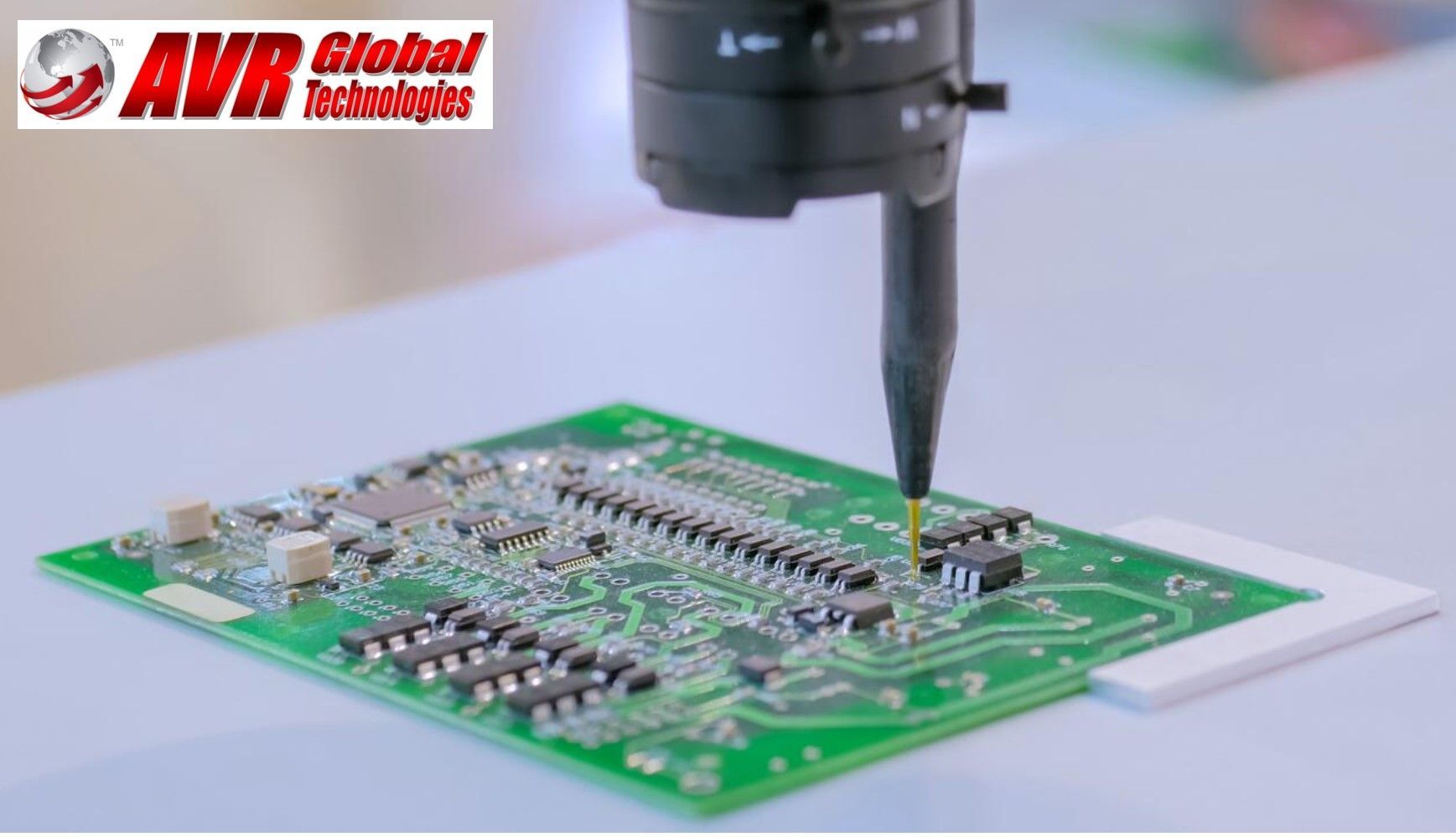

- PCB MFG

- Custom Colors

- Stocking Supply Chain

- Component & Material Testing

- Printers - Custom Label Printing

3D Printers

AVRGT now offers 3D printing service. From prototypes to custom parts, we deliver quality and precision to meet your needs.

Transform your vision into reality with our reliable and efficient 3D printing services. Contact us today to discuss your project and see how we can help bring your ideas to life!

Injection Molding - Plastics / Polymers

AVRGT has extensive experience producing Custom molds for cable strain reliefs, unique connections, box assembly and other customer Injection Molded Parts.

Injection Molding Materials: Choosing the right material

- Acrylonitrile Butadiene Styrene (ABS)

- Nylon.

- High-Density Polyethylene (HDPE)

- Low-Density Polyethylene (LDPE)

- Polycarbonate (PC)

- Polyoxymethylene (POM)

- Acrylic Poly (Methyl Methacrylate) (PMMA)

- Thermoplastic Polyurethane (TPU)

Nylon-Machine Braid

Heavy Duty Machine Nylon core Braid, over custom wire / cable for ruggedized applications. Including Construction equipment cables, heavy truck cables, engine applications and more. Up to 24 nylon core strands. Option Materials for Machine Braid Process: 1. Nylon 2. Polyester 3. Polyethylene Terephthalate (PET) 4. Polyphenylene Sulfide Monofilament (PPS) 5. Nomex

Ultra-Sonic Wire Welding

AVRGT Ultrasonic metal (copper wire) welding is a crucial technology used to ultra-sonically weld copper wires together in Splice Joints. Used in the manufacturing process of wire harnesses (Custom Cables) primarily for automotive (Ford, Toyota, GM, Mercedes, Caterpillar, Volvo, PACCAR Heavy Trucks, John Deere Equipment, etc)

The process involves joining multiple wires with each other in a press that also vibrates at 10K RPM+. Compared with more traditional welding methods like crimping or solder welding, ultrasonic welding offers key advantages. These include the higher quality of weld joints, better process control and low energy consumption.

Interested in our Engineering & Manufacturing services?

Engineering & Manufacturing Support - Contact the Experts at AVRGT